-

Ibhola yeCeramic yokuSila iZirconia zokuSila amaso

Umphezulu we Ibhola yeCeramic yokuSila iZirconia zokuSila amasoigudile, amandla aphuculwe kakhulu, kwaye izinga lomonakalo liyancipha kakhulu.Umonakalo kwisixhobo uyancitshiswa, okwandisa ngokufanelekileyo ubomi benkonzo yezixhobo.Isetyenziselwa ikakhulu ukucola kunye nokusasaza izinto ze-ceramic, ukutya, izithambiso, ipeyinti, iingubo, ii-pigments kunye neenki.

-

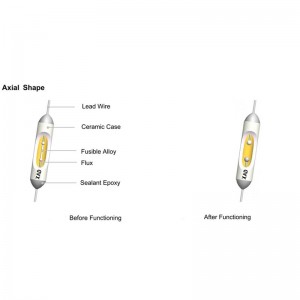

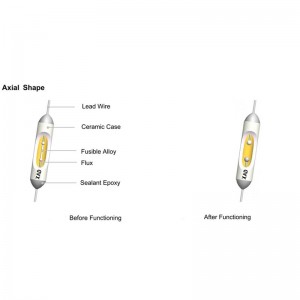

I-alloy cutoff ye-thermal

I-alloy cutoff thermal cutoff lixesha elinye, isixhobo esingabuyiswanga.Isetyenziswa ngokubanzi ekukhuselweni kobushushu obungaphezulu kwezixhobo zombane.Imodeli yokusetyenziswa ikakhulu yenziwe nge-alloy edibeneyo enendawo yokunyibilika ephantsi, i-flux, iplastiki okanye iqokobhe le-ceramic, i-resin yokutywina kunye nocingo olukhokelela.Phantsi kweemeko eziqhelekileyo zokusebenza, i-alloy enokutsha idityaniswe kuzo zombini izikhokelo, kwaye ingxubevange ye-fusible iyanyibilika xa i-alloy cutoff ye-thermal iva ubushushu obungaqhelekanga kwaye ifikelela kubushushu obumiselweyo be-fuse, kwaye kwindima ye-fuse phantsi kwe-contraction ngokukhawuleza ukuya kwiziphelo ezimbini ze-fuse. ukukhokela, ngaloo ndlela ukwaphula isiphaluka.

I-alloy cutoff ye-thermal luhlobo lwe-axial kunye nohlobo lwe-radial, ubushushu besenzo esilinganisiweyo: 76-230 °C, umlinganiselo wangoku: 1-200A, isiqinisekiso sokhuseleko esibandakanya: Rohs CCC, REACH kunye nezinye iimfuno zokusingqongileyo.

-

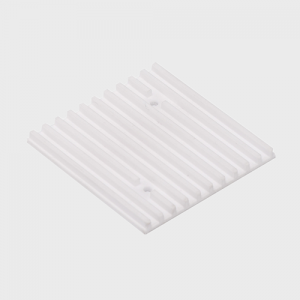

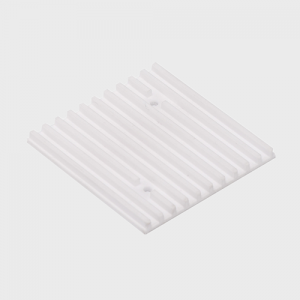

I-Ceramic Heat Sink

Isinki yobushushu beCeramic ubukhulu becala yenziwe ngumaleko wokulahla ubushushu kunye nomaleko wokuqhuba ubushushu, umaleko wokulahla ubushushu kusetyenziso lwesigaba solwelo sotshintsho lwekhemikhali umgaqo ukuya kwi-latex ludaka lokusasazwa okungalinganiyo, ukwakheka komgubo weceramic isakhiwo esibhityileyo, kwaye sidityaniswe ne-sub-micron. umgubo, kwaye emva koko udutyulwe kwisakhiwo sekristale esingenanto kwisakhiwo sokushisa ubushushu, i-porosity yesakhiwo somgobo omncinci womgangatho wokushisa ubushushu phakathi kwe-5% kunye ne-40%, Ubungakanani besuntswana lomgubo buphakathi kwe-90 nm kunye ne-300 nm.Umphezulu woqhagamshelwano kunye nomthombo wokushisa unomgangatho we-thermal conductivity, othatha kwaye uqhube umthombo wokushisa.Ngokusebenzisa indawo ephakamileyo yesakhiwo se-porous somgangatho wokushisa ubushushu, amandla okutshatyalaliswa kobushushu aphuculwa ngokusebenzisa umoya njengomthombo wokushisa ubushushu.

-

IAlumina Ceramic Ring

Amacandelo e-ceramic kwiqondo lokushisa kwegumbi yi-insulator, ngenxa ye-resistivity ephezulu ukuze isetyenziswe kwizixhobo zokugquma, kunye neqondo eliphezulu lokunyibilika, iimpawu eziphezulu zokubilisa, ukwenza izinto zetsimbi kwiqondo lokushisa eliphezulu i-oxidation elula, i-corrosion elula yobuthathaka.Kwaye ngenxa yokuba impahla yemveliso ayinayo imagnethi, ayifuni uthuli, umphezulu akulula ukuwa.

-

Umgubo wegranulation

Njengendlela ebalulekileyo yokubumba kwimveliso ye-ceramic ephezulu, ukubunjwa koxinzelelo kuye kwasetyenziswa ngokubanzi.Ngenxa yeemfuno ezithe chatha ngakumbi nangakumbi zemathiriyeli ekrwada, kuyimfuneko ukusetyenzwa kwezinto zibe ngamasuntswana anokuthi azalise imodeli ngokulinganayo, ukuphucula ukuxinana komzimba oluhlaza kunye nokuqinisekisa ukuxinana kwe-sintering emva kwemveliso ukuze kuphuculwe imveliso. ukumanzi kwezinto zeporcelain, ukuphucula ukusebenza kwe-sintering, ukunciphisa ubushushu be-sintering.Ngoko ke, iUmgubo wegranulationkubaluleke kakhulu ukuvelisa iiseramikhi.

-

Into yoxinzelelo lweceramic capacitive

UnamandlaUxinzelelo lweceramic element(CCP) yimveliso enikezelwe kwimarike yeemoto.Inkqubo yokubumba echanekileyo yamkelwe ukuba iqheleke ukuveliswa kwee-sensor substrates.Isithando somlilo esizenzekelayo esijikelezayo siphucula ukuzinza kwe-sintering ukuvelisa i-sensor substrates engcono.I-substrate yethu inokuchaneka okuphezulu kokucubungula kunye nokuzinza kwezinto eziphathekayo, ezinokuphucula umgangatho wenzwa.

-

Icwecwe lecwecwe laManzi eCeramic

Al2O3 Ceramic Water Valve Plate/Discineempawu zokuxhathisa i-corrosion, ukumelana nobushushu obuphezulu, ukumelana nokunxiba, ukuchaneka okuhle kokuhambelana, ubunzima obuphezulu,njl.

-

Ceramic aluminiyam titanate sprue sleeve bushing

Ceramic aluminiyam titanate sprue sleeve bushingyinxalenye ephambili yoxinzelelo oluphantsi lomatshini wokuphosa i-aluminium.

Ceramic aluminiyam titanate sprue sleeve bushingis inxalenye ebalulekileyo koomatshini bokuphosa uxinzelelo oluphantsi.I-aluminiyam etyhidiweyo ithuthwa ngoxinzelelo olusuka ekubambeni isithando somlilo ngetyhubhu yokunyuka ibe ngumbumba rhoqo kwimizuzu emi-3-5.i-aluminiyam titanate iba yeyona nto ifanelekileyo yeetyhubhu zokunyuka ngenxa yokwandiswa kwe-thermal coefficient, ukuxhathisa ukothuka okuhle kwe-thermal kwaye akukho kumanziswa ziintsimbi ezinyibilikisiweyo.

-

I-Self-lubricating Ceramic Shaft kunye ne-Shaft seal

Ukuzithambisa kweCeramic Shaft / Shaft sealbaye baphucula iipropati eziphathekayo ngesiseko sokugcina amandla aphezulu oqobo, i-asidi kunye nokumelana ne-alkali, kunye nokumelana nokukhuhla kweemveliso ze-alumina.Olona phawu lukhulu kukunciphisa i-coefficient of friction.I-shafts kunye ne-shaft seal usebenzisa le nto ibonisa iinzuzo ezicacileyo.Umzekelo: ubomi obude, ingxolo ephantsi, uzinzo olungcono, kunye nokhuseleko olungcono lwemoto.

I-micro-textured self-lubricating material ye-ceramic iphucula i-complehensive mechanical properties of the Al2O3 material ceramic.Ukuqina kokwaphuka kunye namandla okuguquguquka kweshafti ye-ceramic e-brown self-lubricating yi-7.43MPa · m1/2 kunye ne-504.8MPa, ngokulandelanayo, malunga ne-0.4% kunye ne-12.3% ephezulu kune-alumina ye-ceramic shaft eqhelekileyo, i-coefficient ye-friction ephezulu iyancipha. malunga ne-33.3% kunye ne-friction coefficient encinci iyancipha malunga ne-18.2%.

-

I-Aluminiyam i-oxide yeCeramic shaft / i-Shaft yokutywinwa

Samkela inkqubo echanekileyo yokubumba imveliso enkulu ye-alumina ceramic shaft, i-ceramic bearing.I-alumina ceramic shaft, i-ceramic ethwele ubushushu kunye nokumelana nokubanda, ukuqina kwamandla amancinci, ukunyanzeliswa koxinzelelo, ubunzima bokukhanya, i-coefficient encinci ye-friction kunye nokunye okulungileyo, okusetyenziswa ngokubanzi kwi-motor amanani aphezulu.

-

Isitena se-Alumina seBulb esiHoli / isitena se-Alumina Bubble

Isitena sebhalbhu ye-alumina yimveliso ye-alumina ekhanyayo eyenziwe nge-alumina ye-industrial ngendlela yokunyibilika.Izitena ezikhaphukhaphu zokugquma ezikhanyelayo ezenziwe ngebhalbhu enomgongxo zinokusetyenziswa njengeentsimbi kwiziko lobushushu obuphezulu xa zidibana ngqo namadangatye.

-

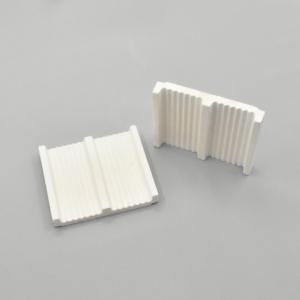

Sintering Fixture

Yethuiipleyiti zokutyhalakwayeiminqamlezozineenzuzo zomxholo we-alumina ephezulu, umxholo wokungacoceki ophantsi, ukumelana nobushushu obuphezulu, uzinzo oluhle lokutshatyalaliswa kwe-thermal kunye nokwandiswa kwe-coefficient ephantsi.