Indlela yokubumba ecinezelayo eyomileyo

I-alumina ceramicItekhnoloji yokubumba ngokucinezela okomileyo ilinganiselwe kwimilo esulungekileyo kunye nobukhulu bodonga obungaphezulu kwe-1mm, umlinganiselo wobude ukuya kwidayamitha ayikho ngaphezulu kwe-4∶1 yeemveliso.Iindlela zokubumba zi-uniaxial okanye i-biaxial.Umshicileli une-hydraulic, oomatshini beentlobo ezimbini, inokuba yi-semi-automatic okanye ukubumba okuzenzekelayo.Uxinzelelo oluphezulu lwe-press yi-200Mpa, kwaye imveliso inokufikelela kwi-15 ~ 50 amaqhekeza ngomzuzu.

Ngenxa yoxinzelelo lwe-uniform ye-stroke ye-hydraulic press, ukuphakama kwamacandelo okucinezela kuyahluka xa ukugcwaliswa kwe powder kuhluke.Nangona kunjalo, uxinzelelo olusetyenziswe ngumatshini wokushicilela luyahluka kunye nomthamo wokuzaliswa kwe powder, okuya kuba lula ukukhokelela kumahluko kwi-shrinkage yobungakanani emva kokucoca kunye nokuchaphazela umgangatho weemveliso.Ngoko ke, ukusabalalisa okufanayo kweengqungquthela zepowder kwinkqubo yokucinezela okomileyo kubaluleke kakhulu ekuzaliseni isikhunta.Nokuba ubungakanani bokuzaliswa buchanekile okanye abukho bunempembelelo enkulu kulawulo oluchanekileyo lwe-alumina eludongeni eyenziweyo.Isiphumo esiphezulu sokuhamba kwamahhala sinokufumaneka xa iinqununu ze powder zikhulu kune-60μm naphakathi kwe-60 ~ 200 mesh, kunye neyona nto ibhetele yokwenza uxinzelelo inokufumaneka.

Indlela yokubumba i-Grouting

Ukubumba iGrouting yeyona ndlela yakuqala yokubumba esetyenziswa kuyoiiseramikhi zealumina.Ngenxa yokusetyenziswa kwe-gypsum mold, ixabiso eliphantsi kunye nokulula ukwenza ubukhulu obukhulu, iinxalenye zemilo enzima, isitshixo sokubumba i-grouting kukulungiswa kwe-alumina slurry.Ngokuqhelekileyo ngamanzi njenge-flux medium, kwaye emva koko wongeza i-agent enyibilikayo yeglue kunye ne-binder, ngokupheleleyo emva kokusila i-exhaust, kwaye emva koko ugalele kwi-plaster mold.Ngenxa yokubhengezwa kwamanzi nge-capillary ye-gypsum mold, i-slurry iqiniswe kwi-mold.I-grouting enomgongxo, kudonga lokungunda lwe-adsorption slurry ubukhulu ukuya kokufunekayo, kodwa kufuneka kugalelwe udaka olugqithisileyo.Ukuze kuncitshiswe ukucutheka komzimba, i-slurry ephezulu yoxinaniso kufuneka isetyenziswe kangangoko kunokwenzeka.

Izongezo ze-Organic kufuneka zongezwe kwialumina ceramici-slurry ukwenza umaleko ombane ophindwe kabini kumphezulu wamasuntswana oludaka ukuze i-slurry imiswe ngokuzinzileyo ngaphandle kwemvula.Ukongezelela, kuyimfuneko yokongeza i-vinyl alcohol, i-methyl cellulose, i-alginate amine kunye nezinye i-binder kunye ne-polypropylene amine, i-gum yesi-Arabhu kunye nezinye i-dispersants, injongo kukwenza i-slurry ilungele ukusebenza kokubumba i-grouting.

Itekhnoloji yeSintering

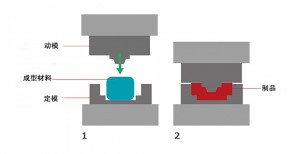

Indlela yobugcisa yokuqinisa umzimba we-ceramic wegranular kunye nokwenza izinto eziqinileyo kuthiwa yi-sintering.I-Sintering yindlela yokususa i-void phakathi kweengqungquthela emzimbeni we-billet, ukususa inani elincinci legesi kunye nokungcola kwi-organic matter, ukwenzela ukuba iinqununu zikhule kunye kwaye zenze izinto ezintsha.

Isixhobo sokufudumeza esisetyenziselwa ukudubula ngokuqhelekileyo sisithando sombane.Ukongeza kwi-sintering yoxinzelelo oluqhelekileyo, oko kukuthi, ngaphandle koxinzelelo, ukucofa okutshisayo kunye ne-isostatic sintering eshushu.Uxinzelelo oluqhubekayo olushushu lunokunyusa imveliso, kodwa iindleko zezixhobo kunye nesikhunta siphezulu kakhulu, ngaphezu kobude bemveliso bulinganiselwe.Uxinzelelo olushushu lwe-isostatic sintering luthatha ubushushu obuphezulu kunye negesi yoxinzelelo oluphezulu njengesixhobo sokudlulisa uxinzelelo, esinenzuzo yokufudumeza okufanayo kuwo onke amacala, kwaye ilungele ukutshiza kweemveliso ezintsonkothileyo.Ngenxa yesakhiwo esifanayo, iipropathi zezinto eziphathekayo zonyuka nge-30 ~ 50% xa kuthelekiswa nokucofa okubandayo.I-10 ~ 15% ephezulu kunoxinzelelo oluqhelekileyo lokucofa okutshisayo.

Ixesha lokuposa: May-12-2022